Polycrystalline diamond dies

For the production of PCD inserts are used:

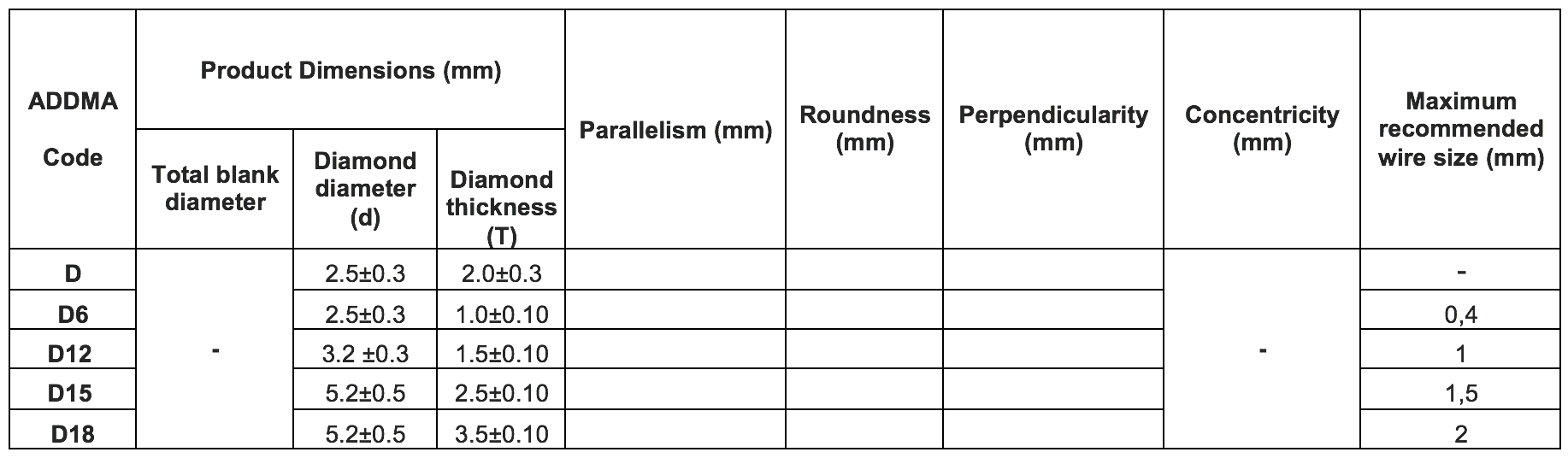

1. Self-Supported heksagonal Die Blanks

Self-Supported heksagonal Die Blanks, maximum recommended die size for „soft” nonferrous Wire. „Hard” Wire diamentem normally should not exceed 65% of this diameter.

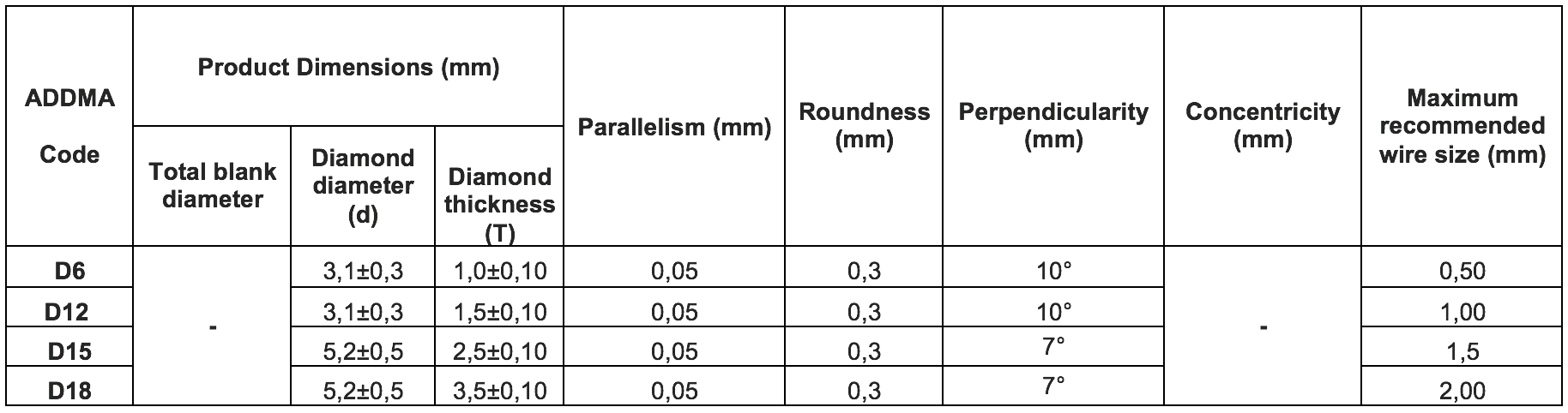

2. Self-Supported Die Blanks

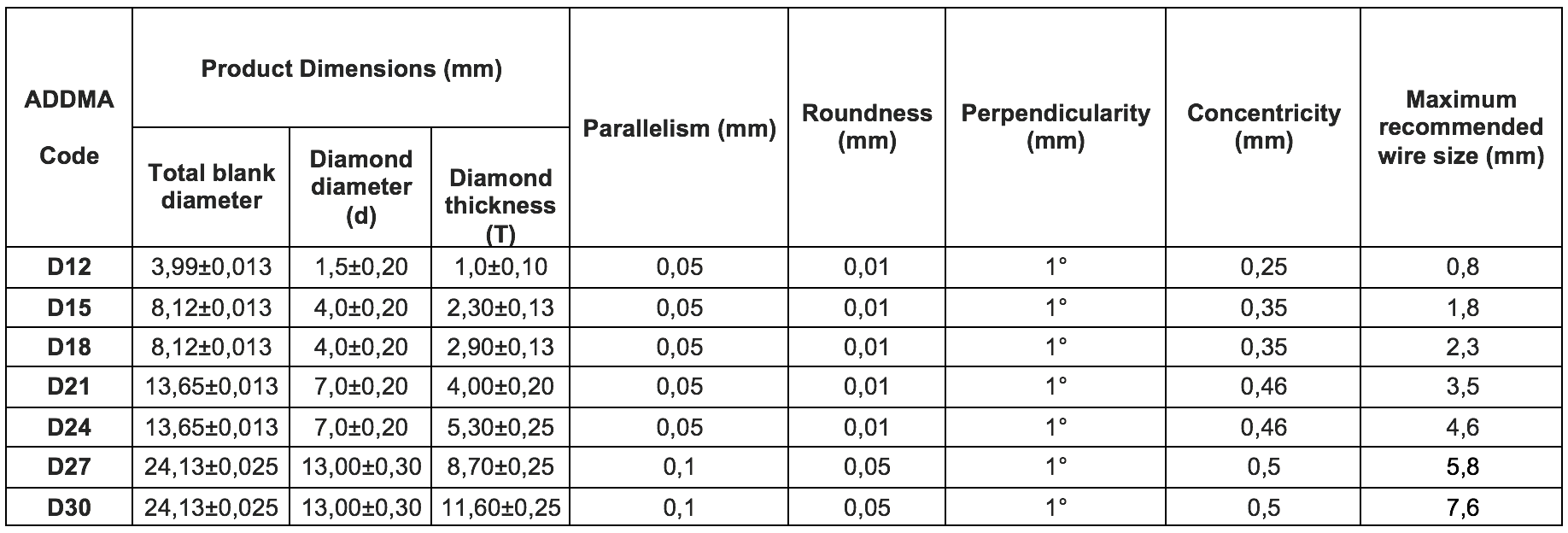

3. Tungsten Carbide Supported Die Blanks

Self-Supported heksagonal Die Blanks, maximum recommended die size for „soft” nonferrous Wire. „Hard” Wire diamentem normally should not exceed 65% of this diameter.

Polycrystalline Diamond Dies

Total Bore Diameter Tolerances PDD Wire Drawing Dies-New and Recuts

|

Size Rang |

Standard tol. |

Out of roundnes |

| > 0.10÷0.20 | 1.5 | 0.8 |

| > 0.20÷0.50 | 2.0 | 1.3 |

| > 0.50÷1.00 | 2.5 | 1.5 |

| > 1.00÷1.50 | 3.0 | 2.0 |

| > 1.50÷2.50 | 3.5 | 2.5 |

| > 2.50÷4.50 | 4.0 | 3.0 |

| > 4.50÷6.50 | 4.5 | 3.5 |

| > 6.50÷8.00 | 5.0 | 4.0 |

Standard Casing Size

|

Blank size |

Standard casing |

| D-6; D-12 | 25 – 28 x 6 – 8 |

| D-15; D-18 | 25 – 28 x 10 – 12 |

| D-21; D-24 | 25 – 28 x 12 |

| D-27; D-36 | 38 x 22 |

Typical Die Specification for Various Wire Materials

| WIRE MATERIAL | REDUCTION ANGLE [2a] |

BEARINGLENGTH |

| Bare Copper | 18° ± 2° | 25% ± 10% |

| Aluminium | 20° ± 2° | 25% ± 10% |

| Tin or SilverPlated Copper | 20° ± 2° | 25% ± 10% |

| Stainless Steel | 15° ± 2° | 35% ± 10% |

| Tungsten | 14° ± 2° | 30% ± 10% |

| Brass or Copper Covered Steel | 12° ± 2° | 30% ± 10% |

ORDERING INFORMATION:

NOTA Zakład Mechaniki Precyzyjnej provide the quality needed for optimum wire drawing efficiency. For enhanced order processing, please verify your product requirements for the following die specifications.

| 1. 2. 3. 4. 5. 6. 7. 8. |

Hole Size Hole Size tolerance Reduction Angle Bearing Length Quantity per Hole Size Casing Dimensions Wire Material Blank Number |

…………………… …………………… …………………… …………………… …………………… …………………… …………………… …………………… |

PRINCIPLES OF WORK with diamond dies

| 1. | Do not exceed the maximum diameter recommended manufacturers liners for the size of insert, because you can not build a full die geometry |

| 2. | Maximum diameter of hard steel wires should not exceed 65% of the diameter recommended for the size of inserts because it threatens to damage the tool |

| 3. | The die should be subjected to repolishing already at the time the mat at the interface between the material stress gauges on the cone work, this will allow for extension of time dies, admission to the formation of the deep drawing ring makes it necessary to change diameter during regeneration or cracks dies |

| 4. | It is necessary to filter the emulsion lubricant in wire drawing machine constantly and control its composition and significantly extend the life of dies and ensure high quality of the surface of wire |

| 5. | Drawing wire at high speeds, reduce the length of the calibration |

| 6. | Dies with fine-grained blanks- propose to use to draw on the ready when it is important to the quality of the surface of a wire and drawing steel wire and covered wire (eg, welding wires) |

| 7. | Dies with coarse- grained blanks- propose to use to draw large diameter of color wires, this will get big performance from one die |

| 8. | In the process of drawing tungsten and molybdenum on the hot atmosphere taper dies in work zone will minimize the effect of oxidation of diamond and increase its vitality |